High Speed Pillow Block Bearing

- About products and suppliers:

Your business relies on your woodworking machines being in good working order. If one breaks, it can be very costly to replace. This is where Alibaba.com comes in. If you know the details of the missing part, you can simply order from the high speed pillow block bearing range. Take care when placing your order to make sure the relevant part is compatible with the machine. Again, it is important to be careful when fitting or replacing the part, as mistakes can lead to injury, particularly when heavy machinery is involved.

When you know which high speed pillow block bearing you need, choose the correct wholesaler from the range available on Alibaba.com. You can buy in bulk if this is a part that regularly needs replacing, which will mean you always have replacement options to hand. Or simply buy the single item as you see fit. Whatever the size of your order, Alibaba.com’s customer service team are there every step of the way. Once the purchase has been placed, you can track your order – which is useful if you are waiting for ahigh speed pillow block bearing to being your woodworking again.

Head on over to Alibaba.com today and take a look at the high speed pillow block bearing options today. Once you’ve made your choice, purchase can happen in just a few easy clicks. Whether you’re looking for a sanding drum part or a delicate spindle, Alibaba.com has what you need.

- Related Searches:

Sourcing Guide For High Speed Pillow Block Bearing:

With hundreds of thousands of products to choose from and an ever growing product range, your industrial equipment needs are sure to be met here. Our China manufacturers & suppliers will provide a full-service to keep you up and running and meet your unique equipment requirements. If you are interested in China High Speed Pillow Block Bearing, You will be amazed by the variety of the product choices such as ball bearing, pillow block bearing, bearing. Besides, their competitive & cheap price of High Speed Pillow Block Bearing factory would get you an edge in your own market. It’s well known that product quality and safety is a stronger priority for this equipment industry and also for the buyers, here you are offered a greater chance to find trustworthy manufacturers & factories who are delivering high levels of performance, efficiency and reliability in their products all the time. With thousands of quality suppliers & manufacturers, we are sure that they can provide all equipment for sale, services and solutions for your various industrial applications.

Easy Sourcing

The Installation Of High Speed Pillow Block Bearings

First, the installation of the top wire locking high speed pillow block bearings:1. Check the accuracy of the shaftBefore installing the bearing, check whether the dimensional tolerance of the shaft is qualified, whether the shaft has any problems such as bending, bumping, burr, etc., and add some lubricating oil on the shaft.2. Check the rigidity and flatness of the mounting surface

The rigidity of the frame on which the seated bearing is mounted should be sufficient, and the flatness of the mounting part should not exceed 0.15 mm.3. Mounting high speed pillow block bearingsTo avoid hitting the bearing with a metal such as a hammer for installation. In particular, for a bearing with a retaining ring seal, when the bearing is struck, the retaining ring may be displaced inward, and the inner seal ring may be in contact with the inner seal ring to cause friction during operation, causing the bearing to rotate unsatisfactorily or the temperature to rise sharply to burn the bearing. When the bearing inner hole and the shaft are tightly fitted, it is recommended to press the inner ring end face for installation.

5. Tightening the high speed pillow block bearings top wireThe torque to lock the top wire is based on the recommended torque.6. Retightening the bearing housingExcessive torque of the locking bolt may cause deformation of the bearing housing. Use proper tightening torque to lock the bolt.

Contact: Ellen

Recommended Reading: Does Mattress Firm Give Military Discounts

Pillow Block Bearing Specifications

The pillow block bearing has the following specifications:

How To Install Pillow Block Bearing

The installation of the pillow block bearing is very easy and simple:

1) Check and Clean the Shaft

2) Position the Bearings on the Shaft

Now properly place the bearing on the shaft. If you want to tap the bearing in its place, then use a mild steel tube, block of hardwood, or a hammer against the inner race. Avoid hitting or applying pressure to the seal or body.

3) Lightly Bolt the Housing to the Mounting Structure

Lightly screw the casing to the mounting frame to lock the shaft. Now, connect the housing mounting bolt slots with high-strength spring washers or high-strength flat washers. This will prevent it from loosening.

4) Align the Final Mounting Position

Before tightening the bolts, align the bearing unit with a rubber mallet or by hand to determine the final installation position.

5) Securely Bolt the Housing to the Mounting Structure

After aligning the bearing, tightly secure both units to the mounting frame.

6) Ensure the Axial motion of the Shaft

Now confirm the axial motion of the shaft through the bearing hole to ensure proper alignment. If it cant move axially, loose the housing and re-adjust the shaft.

7) Tighten Both Collar Set Screws

Read Also: Does Financing A Mattress Build Credit

Koyo Tr Nsk Ntn Nachi Asahi High Speed Pillow Block Bearings Ucfcx11

Certification

Nurul Azim

Pichanut K.

| original package, Netural package, single package, Wooden package+pallet, Carton package+pallet, or as customerized. | |

| Delivery Time: | 2-7 days after receiving the payments or deposit |

|---|---|

| Payment Terms: | L/C, T/T, Paypal, Western union, |

| Supply Ability: |

KOYO TR NSK NTN NACHI ASAHI High Speed Pillow Block Bearings UCFCX11-36

2. Brand Name: UMT, NTN, FYH

3. Model Number: NSK Pillow block bearing UCFCX11-36

4. Place of Origin: Japan

5. Dimensions: mm

8. Housing material: Black oxided or Zinc plated

9. Material: Chrome steel, stainless steel

10. Precision Rating: ABEC-1, ABEC-3, ABEC-5,ABEC-7

11. Vibration Level: V1,V2,V3

Description:

Pillow blocks, the most commonly used type of mounted units, are designed to provide shaft support where the mounting surface is parallel to the shaft axis. The bolt holes are usually slotted for adjustment during mounting. Pillow blocks are supplied in a variety of configurations. Pressed steel pillow block bearings are also available for light-duty applications.Car Multimedia Navigation System

What Are Pillow Block Bearing Units And Where Are They Used

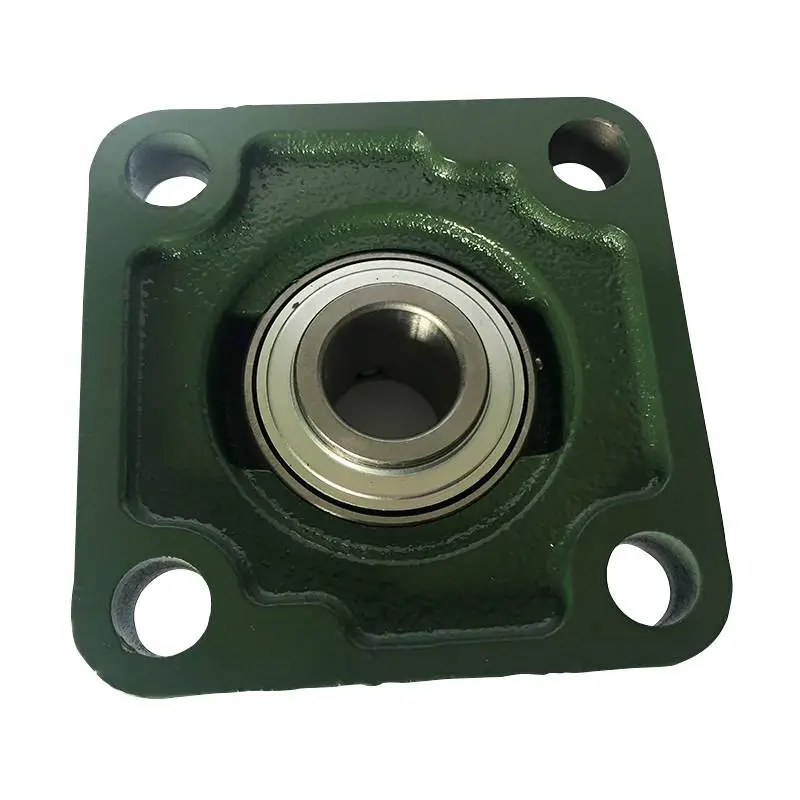

A pillow block ball bearing unit comprises of a robust mounting bracket which houses a radial ball bearing.

The exterior housing is generally made from cast iron as standard, but other material options such as pressed steel or thermoplastic are available to suit environmental conditions and industry requirements.

Pillow blocks can be found in almost every industry, with pillow block ball bearing units particularly suited to applications with a high speed and a low to moderate load.

These units have a variety of sealing options and end covers to suit even the most contaminated of environments.

Recommended Reading: Where Can I Dispose Of A Mattress

What Is A Pillow Block Bearing

April 9, 2015 By Mike Santora

A pillow block bearing consists of a mounting bracket that houses a bearing and is used in low-torque, light load applications.

With this configuration, the pillow block is bolted to a foundation, securing it, while the shaft and the inner ring of the bearing are free to rotate. Usually made of gray cast iron, pillow blocks come in two types, split or unsplit. With split pillow blocks the housing element or cap can be separated from the base. An unsplit pillow block is made from one solid piece.

Often, the terms pillow block bearing and plumber block bearing are used synonymously but the two are different devices. Both are designed to be mounted to a surface through mounting holes on the base of the block. They differ in that plumber block bearings do contain an inner bearing and they are also designed for higher loads and more corrosive environments.

For information on roller bearing pillow blocks, click here.

What Is Pillow Block Bearing

The pillow block bearing is also known as a plummer block. A pillow block bearing is a base that supports the rotating shafts by using compatible bearings and different accessories. This type of bearing contains a mounting block . The bearing is installed inside the mounting block.

The pillow block bearings are most commonly used in low-torque applications. The slots or bores in the bearing base or feet of the bearing allow for easy assembly and adjustment.

The pillow block bearing housing has the following two types:

The pillow block bearing has different types, such as tapered, roller, and ball bearings.

Don’t Miss: How Often Should You Change Bed Mattress

Material Selection For Pillow Block Bearing

1) Housing Material

The main function of the housing is to protect the internal parts of the bearing from damage due to external material. Following are the most common materials used for the construction of the pillow block bearing housing:

iii) Stamped steel: Stamped steel is mild carbon steel that is stamped instead of machined. These bearings have low cost than the cast or machined pillow block bearings. These bearings are ideal for light load carrying applications.

Iv) Plastic: Plastic represents synthetic, organic, or processed materials, most of which are high molecular weight thermoplastic or thermoset polymers. The most famous plastic materials include Teflon, nylon/polyamide, and Acetal.

V) Stainless steel: It has high corrosion and chemical resistance ability. It also has a relatively high-pressure rating.

2) Bearing Material

The bearing is a most important part of the system. The bearing material highly affects the performance of the system. The following materials are most commonly used for the construction of bearing:

ii) Stainless steel: It is a corrosion and chemical resistant material. It has a relatively high-pressure rating.